Our Processing

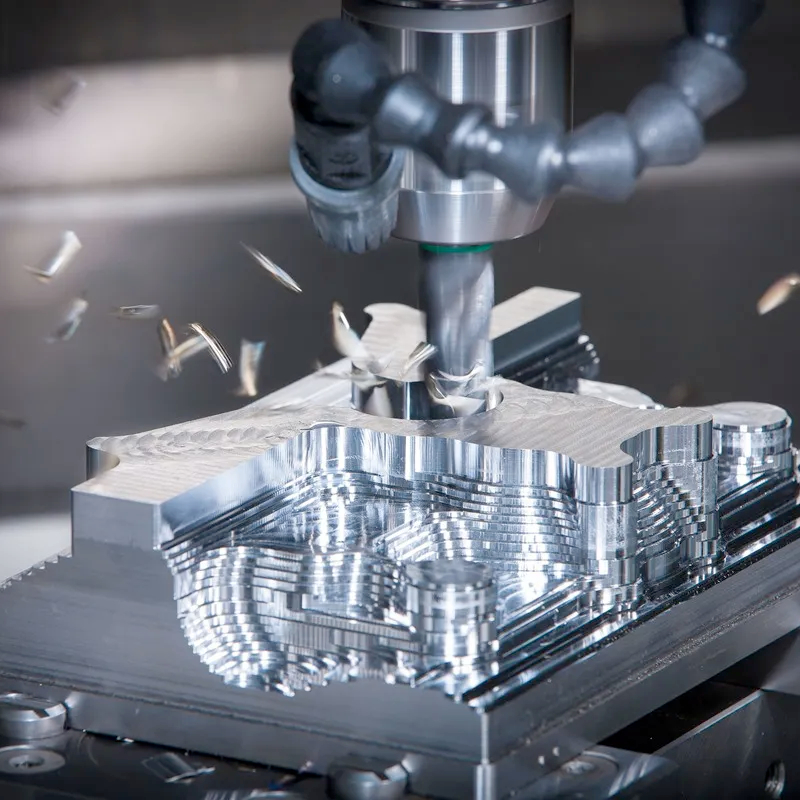

MILLING

Mechanical milling, obtained by means of milling inserts, is a machining by chip removal with which to obtain a vast range of surfaces through the rotary motion of a multi-edged tool .

Milling productivity can be optimized in various ways. It is important to choose the right tool for the application, but the choice of cutting data is equally critical.

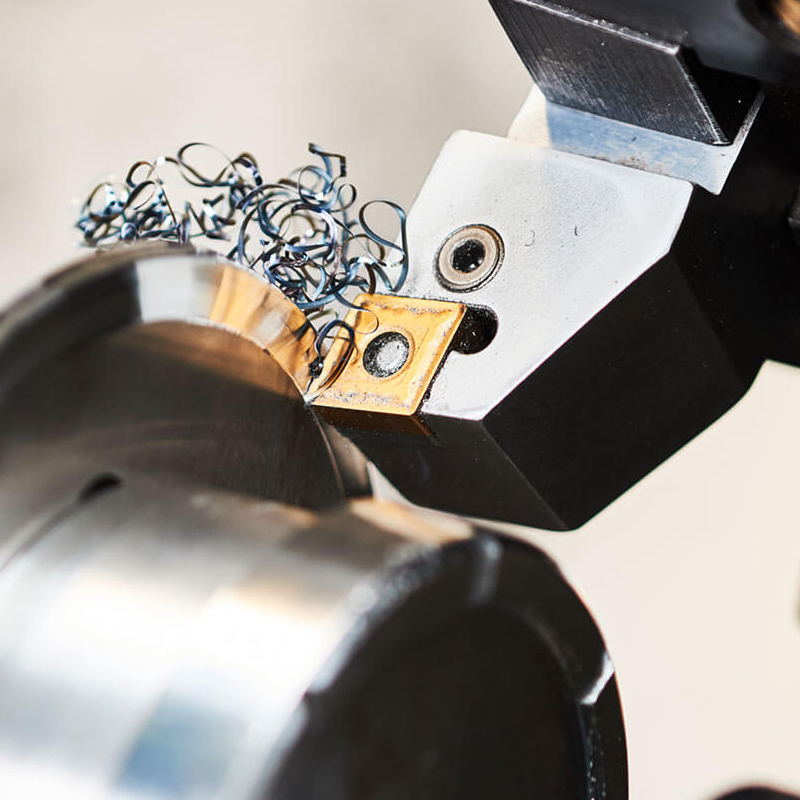

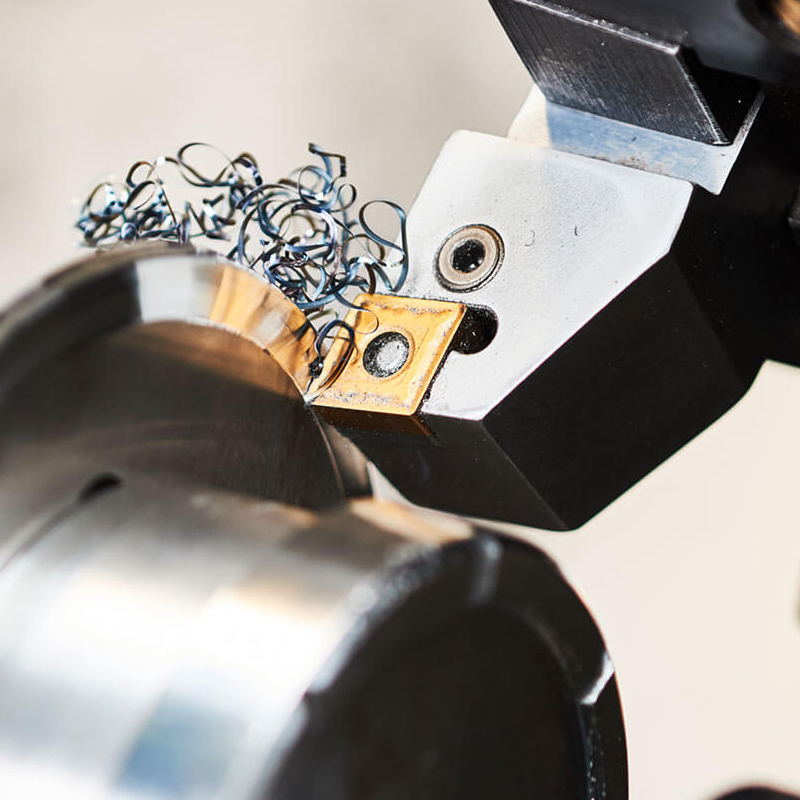

TURNING

Turning is an industrial production process obtained by chip removal. Turning is defined by a rotary motion of the piece and a mostly rectilinear motion of the tool. The cutting edge of the tool penetrates the material of the piece and detaches the excess part (stock) thus forming a chip.

According to the degree of finish, the process is called: ROUGHING OR FINISHING.

CUTTING

Parting off is mainly performed in machines with a bar feeder, which are often used for series production

Tipology:

Shallow cut

Medium truncation

Deep parting

Parting without burrs and pegs

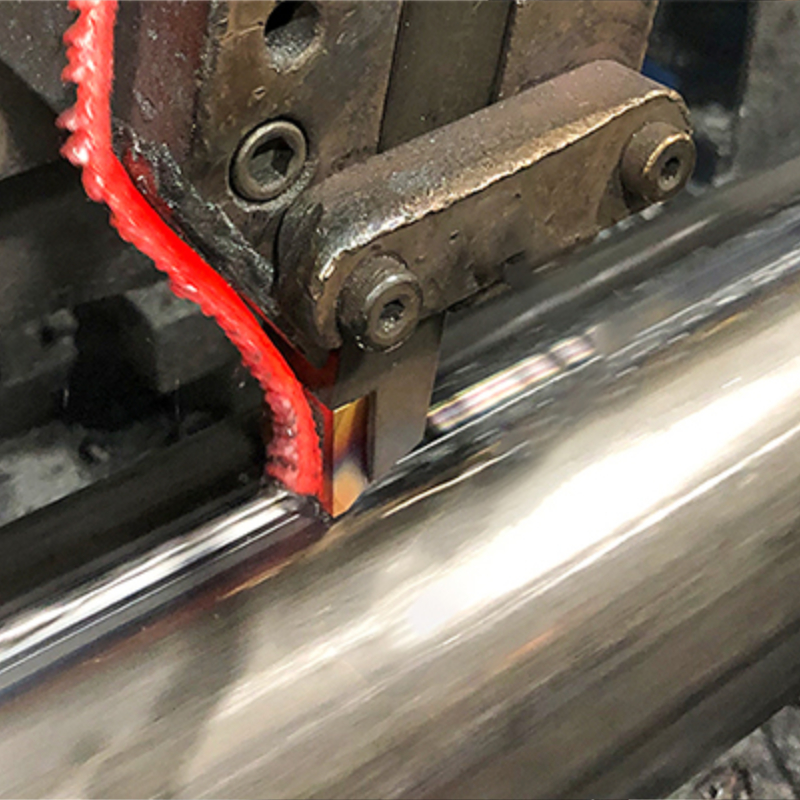

DECORNING

During the welding process of the edges of the profiled steel strip, a weld bead is formed internally and externally to the tube or profile formed.

These must be removed through systems and equipment which for the external seam go under the name of EXTERNAL SCREWING

if inside, INTERNAL SCREWING.

ENG

ENG ITA

ITA